The Growing Importance of Embedded Systems in Industrial Automation

- Amantya

- 2024-06-27, 09:39 am

- Importance of Embedded Systems

- Embedded Systems , Industrial Automation , Amantya's Smart Automation Solutions

Embedded systems have become increasingly vital in today's automation-driven world. Specifically in industrial automation, they are essential for accelerating production processes and managing factory systems efficiently. These systems transform industrial automation by enhancing efficiency, precision, and reliability across workflows. From assembly line control, precision control, and robotic control to supply chain and logistics automation and predictive maintenance, embedded systems provide the backbone for advanced control, monitoring, and management, transforming traditional operations into high-tech processes and solutions.

Study by market.us |

Our first of the three-blog series on the topic will explore how embedded systems add value to the industrial automation domain.

What are Embedded Systems?

An embedded system is a hybrid of software and hardware, often featuring a single-chip microcontroller or microprocessors, memory, input/output interfaces, and software designed to control specific functions. These systems can operate independently or as part of a larger system. Key attributes of embedded systems include power efficiency, compact size, high reliability, precision, and adaptability.

Embedded Systems in Industrial Automation

Embedded systems are at the core of industrial automation across industries, including manufacturing, industrial machines, automobiles, medical devices, agriculture, telecom, and more. They facilitate seamless communication between machinery and control systems, enhancing overall efficiency and maximizing performance in challenging environments that often demand precision. They enable the incorporation of next-generation technologies like AI, ML, and IoT into industrial processes, allowing real-time data collection and analysis, which optimizes production lines, reduces downtime, and enhances product quality.

How Embedded Systems Add Value to Industrial Automation

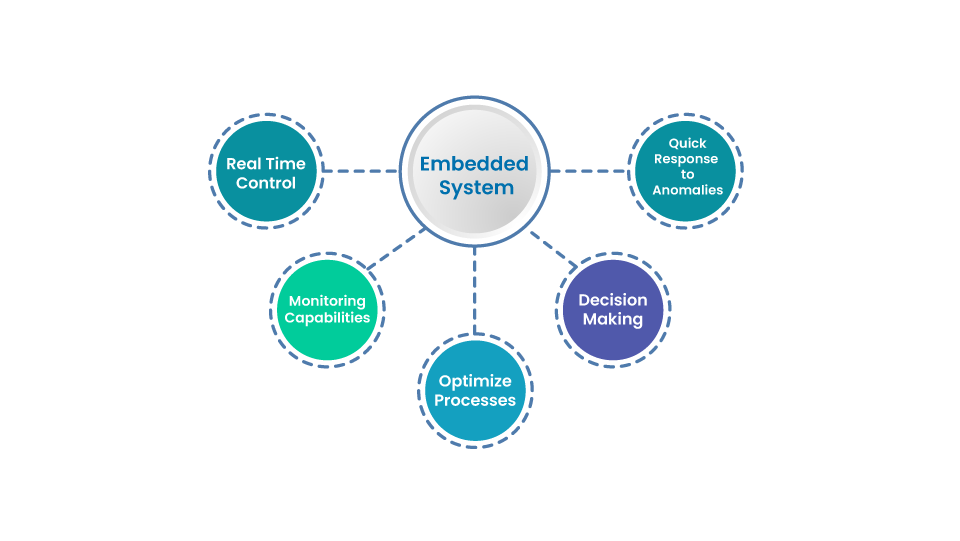

Listed below are some aspects of industrial automation that are increasingly enhanced by embedded systems:

Robotics and Motion Control

The integration of embedded systems in robotics has transformed manufacturing. These systems control the precise movements of robots, enabling tasks such as assembly, welding, painting, and material handling. With real-time processing capabilities, embedded systems ensure high accuracy and repeatability, essential for maintaining product quality.

Process Control and Monitoring

Embedded systems are critical in process control and monitoring, ensuring that industrial processes operate within predefined parameters. They collect sensor data, process it, and trigger actions based on the results.

Drones and AGVs for Precise Indoor Navigation and Task Automation

Integrating drones and Automated Guided Vehicles (AGVs) with embedded systems significantly enhances indoor navigation and task automation. Embedded systems enable precise control and coordination of these devices, allowing them to navigate complex indoor environments accurately. This precision facilitates inventory checks, material transport, and equipment inspection. By leveraging real-time data processing and advanced sensors, embedded systems ensure that drones and AGVs operate efficiently, reducing human intervention and increasing overall productivity in industrial settings.

Supply Chain and Logistics Automation

Embedded systems enhance supply chain and logistics operations by automating inventory management, tracking shipments, and optimizing routes. RFID tags, GPS, and embedded controllers ensure accurate tracking and efficient management of goods from production to delivery. This results in reduced costs, improved delivery times and enhanced overall supply chain efficiency.

Predictive Maintenance

Embedded systems utilize machine learning and deep learning algorithms to monitor the health and performance of industrial equipment. These systems can identify irregularities and anticipate malfunctions by analyzing temperature, vibration, and operating conditions. This proactive approach reduces unexpected downtime and extends the lifespan of machinery through timely maintenance interventions.

Warehouse Logistics

Embedded systems enhance warehouse logistics by automating storage, retrieval, and transportation processes. They control automated guided vehicles (AGVs), robotic arms, and conveyor systems, ensuring efficient and accurate handling of goods. This automation improves inventory management, reduces operational costs, and enhances overall productivity by minimizing human errors and optimizing workflows.

Quality Control and Fault Detection

Embedded systems are crucial in maintaining high-quality control and safety standards in industrial environments. They continuously monitor variables such as pressure, speed, and dimensions to ensure products meet specified standards. Additionally, they integrate sensors for process control, temperature regulation, and pressure management, enabling rapid fault detection and response to maintain optimal operating conditions.

Energy Management

Embedded systems play a critical role in energy management by tracking and analyzing energy consumption, regulating power distribution, and optimizing energy use across industrial facilities. These systems continuously monitor power usage, equipment efficiency, and operational patterns, providing insights that lead to significant energy savings and improved sustainability. They help regulate power distribution and manage consumption effectively.

Remote Monitoring and Maintenance

Embedded systems enable remote monitoring and maintenance of industrial equipment, allowing for real-time diagnostics and proactive scheduling of maintenance tasks. This capability reduces the need for on-site inspections, lowers maintenance costs, and ensures the continuous operation of machinery by addressing issues before they lead to significant failures.

Industrial Safety Systems

Embedded systems are used in industrial safety applications to monitor and control hazardous processes. They integrate sensors for detecting gas leaks, fire, and equipment malfunctions, triggering alarms and automated shutdowns if necessary. These systems are vital for maintaining a safe industrial environment by ensuring compliance with safety regulations and protecting workers.

Environmental Monitoring

Embedded systems facilitate continuous monitoring of environmental parameters such as air and water quality, weather conditions, and pollution levels. Sensors collect and analyze data in embedded systems to provide real-time insights and alerts. This application is crucial for regulatory compliance, public health, and the management of natural resources, helping mitigate the impact of environmental hazards.

To Conclude

As the demand for automation increases, embedded systems will play an increasingly crucial role in industrial automation. These systems can enhance productivity, efficiency, and innovation in industrial processes. Furthermore, integrating embedded systems with advanced technologies such as the Internet of Things (IoT), Cloud, and Artificial Intelligence (AI) will expand their applications, enabling enterprises to grow and thrive exponentially in the dynamic industrial automation landscape.

The Amantya Advantage

Amantya provides a broad spectrum of services for building advanced embedded systems for industrial automation. Our comprehensive domain experience and capabilities in hardware and software for industrial automation position us uniquely to offer you end-to-end support in converting your idea into a future-ready product. We help our clients leverage solutions like embedded engineering systems, cloud integration, and indoor localization techniques to enhance efficiency and precision in industrial settings.

Want to know how Amantya can help you integrate embedded systems into your existing or future projects? Contact us at connect@amantyatech.com, and our team will be happy to assist you.